After All These Years

April 19, 2022 | By John Siegenthaler

The movement toward decarbonization is one of the biggest opportunities set before the North American hydronics market.

(image: Adobe Stock)

I’ve been designing hydronic systems for 44 years. As with most technologies, there have been tremendous changes in what a “typical” residential hydronic heating system looks like today compared with what it did in 1978.

Back then it was common to see a single cast-iron boiler—fired by natural gas or fuel oil—supplying a distribution system consisting of one to three zones of finned-tube baseboard.

The boiler usually had a “tankless” coil heat exchanger for providing domestic hot water, and the water temperature leaving that boiler was 180F (82C) or higher.

Although it’s possible to create such a system today, most informed hydronic system designers would likely try to talk you out of it. I know I would.

Change is Constant

So why should anyone alter an approach that has kept tens of thousands of North American homes comfortable for decades?

The “short answer” would be the greatly improved hardware and design methods that exist today. Here are a few examples that have all taken place during my career:

- The introduction of cross-linked polyethylene (PEX) tubing to North America and a subsequent resurrection of radiant panel heating.

- The introduction of modulating/condensing (mod/con) boilers that pushed thermal efficiency (annual fuel utilization efficiency/AFUE) from mid-80% into the mid-90s.

- Controls that morphed from those using springs, glass bulbs partially filled with mercury, and capillary tubes, to microprocessor-based controls that can manage entire multi-load systems and wirelessly communicate with installers.

- Circulators with electronically commutated (EC) motors that can automatically adapt their operation to the pressure and flow requirements of a hydronic system.

- WiFi thermostats that let you change the temperature in a zone from almost anywhere in the world.

- A broader understanding of the importance of and methods for implementing hydraulic separation in multi-circulator systems.

Many of these introductions were a really “big deal” when they occurred. Today, most of them have reached commodity status. They are readily available from multiple suppliers and used on a high percentage of system installations.

There’s little doubt that this new hardware, when properly applied, allows modern hydronic systems to provide even better comfort and convenience than that available 40-plus years ago.

An unprecedented Trend

So much for the “short answer.”

The “long answer” is based on a relatively new word in our social vocabulary: Decarbonization. The concept that the human race must reduce our carbon emissions as a prerequisite to survival on this planet.

There are widely varying beliefs on how “decarbonization” should be dealt with. They range from complete denial that any action is needed, to proposals that would radically change just about everything we do.

I suspect that such a spectrum of opinion exists among those reading this article. That’s okay, but read on to see that there is a unifying concept that can emerge from all this.

Possibilities rather than Politics

I learned long ago not to pepper politics into my presentations or writing. Rather, let me attempt a rational assessment of our current market situation.

It appears highly likely that the energy used by future hydronic heating and cooling systems will be increasingly supplied through electricity and less by the burning of fossil fuels.

Let me attempt another (practical) inference to that last sentence: The global movement away from fossil fuel and toward electrification could very well be one of the biggest opportunities ever presented to the North American hydronics industry.

To understand why that opportunity has been laid before us, let’s start by looking backward. Hydronic systems were the “norm” in many buildings prior to the availability of central cooling systems, which began entering the North American market in the late 1950s.

Central cooling was a monumental step forward for the HVAC market. It shifted focus to forced air distribution systems, which could deliver that highly anticipated cool/dry air in the summer, as well as heated air in the winter.

The compromises associated with forced air heating, including air temperature stratification, dirt accumulating in ducting, and low interior relative humidity due to increased air leakage, were tolerated because, come summer, the cool/dry air delivered by those forced air systems was considered a “godsend.”

Although mid-twentieth century hydronic systems provided excellent comfort, they didn’t provide cooling, and that, more than anything else, eroded their market share into single digits as forced air systems leveraged their ability to provide heating and cooling.

Think about it. As a comfort pro, how many times have you encountered someone who was absolutely “sold” on the benefits of hydronic heating, only to abandon ship when told that a completely separate system would be required for cooling?

It doesn’t have to be that way anymore. Water-to-water heat pumps connected to geothermal loops, as well as air-to-water heat pumps, can provide superior comfort heating, domestic hot water, and chilled water for cooling.

They fit beautifully into the ambitious electrification efforts now underway in just about every part of North America. They enable a mechanical contractor to provide answers to questions like: “I really want to use radiant floor heating in my new home, but what do I do about cooling?”

They also allow that contractor to provide a “total comfort (and DHW) solution,” take sole responsibility for the system, and profit from providing additional materials and labour on each sale.

For Example

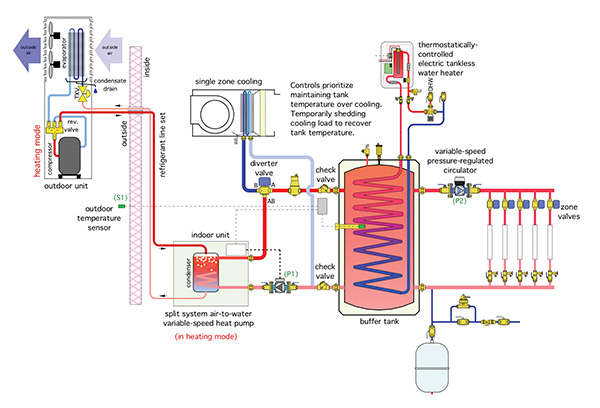

Like most things related to hydronics, there are many possible system configurations that involve a heat pump along with space heating, cooling, and domestic water heating loads. One of my favorite approaches uses an air-to-water heat pump supplying heat to a buffer tank that in turn supplies a zoned space heating distribution system. Figure 1 (below) shows the concept.

Figure 1: a typical set-up using an air-to-water heat pump supplying heat to a buffer tank that in turn supplies a zoned space heating distribution system.

The heat emitters could be radiant panels, fan-coils, panel radiators, or a combination of all three. They should all be sized to provide design load output to their associated spaces using a supply water temperature no higher than 120F (49C).

The buffer tank contains a high surface area coil heat exchanger. Its purpose is to preheat domestic water through the majority of the required temperature lift. An electric tankless heater provides any required temperature boost.

In cooling mode the chilled water leaving the heat pump goes to the coil of a ducted air handler, which provides cooling to the entire building.

Note that the heat pump is labelled as variable-speed. It uses an inverter-driven compressor that allows cooling capacity to be adjusted as necessary (and within the limits of speed control) to supply a constant 45 to 50F (7 to 10C) stream of chilled water to the air handler. This approach eliminates the need to chill the buffer tank in summer. The latter can remain heated to provide most if not all of the domestic hot water requirement.

In summer the control priority is keeping the buffer tank heated to ensure a high percentage of domestic water heating. Cooling can be temporarily interrupted to bring the tank up to temperature.

Air-to-water heat pumps can be part of a total comfort solution.

There for the Taking

Hydronic pros who choose to read the “tea leaves” regarding heat pumps, and act smartly on that information, will surely profit.

Opportunities for integrating heat pumps into hydronic systems are already occurring in many areas of North America. Demand will increase as provincial and state electrification goals continue to shape the market.

The movement toward decarbonization is one of the biggest opportunities set before the North American hydronics market in decades. With all due respect to product development, this opportunity is far more consequential than next year’s new offerings for boilers, WiFi thermostats, or press tools.

It’s also an opportunity that comes with many “advocates” such as architects, low energy home builders, Solar PV installers, utility reps, regional energy planners, environmental proponents, and yes – even politicians.

The words “heat pump” will grab their attention, setting up the opportunity for you to explain how hydronics technology completes the comfort part of the offering. It’s the perfect opportunity for you to “evangelize” your passion for hydronics to a much broader and highly receptive audience. <>